Creating custom pieces from scratch can feel like magic. It’s about turning ideas into tangible products. Two key processes in this journey are sandblasting and laser cutting. Each of these techniques plays a vital role in the world of custom fabrication, helping to bring creative visions to life.

Sandblasting: A Powerful Tool for Surface Preparation

Sandblasting is one of the most effective ways to prepare surfaces for further processing. The process involves blasting abrasive materials, like sand, at high speeds against a surface. This action cleans, smoothens, or shapes the material, making it ready for painting or other finishes.

Think of sandblasting as a gentle yet powerful scrub for materials. It can remove old paint, rust, or any imperfections that might ruin the final look of a product. For instance, if a designer wants to create a sleek metal sculpture, sandblasting is often the first step. It ensures that the surface is free of blemishes, allowing for a perfect finish later on.

Moreover, sandblasting can create interesting textures. By changing the type of abrasive material or the pressure used, artisans can achieve different effects. This flexibility allows for creativity, giving each piece a unique touch. The ability to prepare and enhance surfaces makes sandblasting an essential step in custom fabrication.

Laser Cutting: Precision at Its Finest

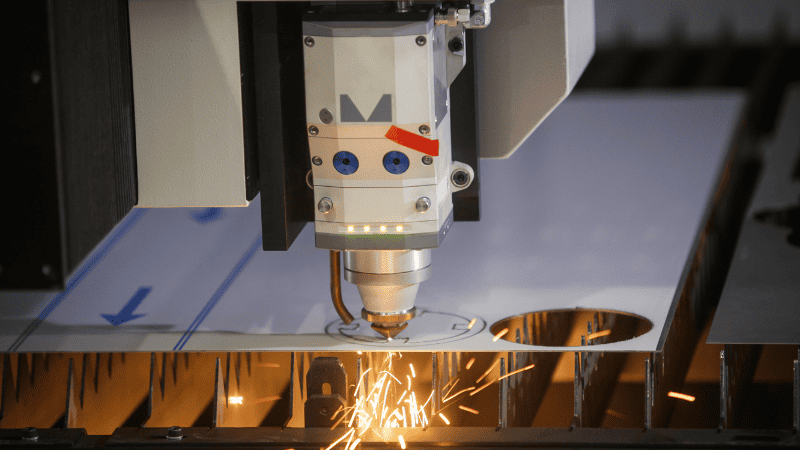

Laser cutting is another critical technique in custom fabrication. It uses a focused beam of light to cut through various materials like metal, wood, and plastic. This method offers incredible precision, allowing for intricate designs and clean edges.

Imagine a designer with a complex pattern in mind. With laser cutting, they can bring that vision to life with exactness. The laser can cut shapes that are incredibly detailed and precise. This accuracy means that every piece fits perfectly, reducing waste and saving time during assembly.

The speed of laser cutting is also a significant advantage. Traditional cutting methods can be slow and labor-intensive, but lasers can cut through materials quickly and efficiently. This means that what could take hours can now be completed in minutes, speeding up the entire production process.

Laser cutting is also versatile. Whether working with thin sheets of metal or thicker materials, lasers can handle a wide range of projects. This adaptability is vital in a world where custom designs are often one-of-a-kind.

Combining Techniques for Unique Creations

When sandblasting and laser cutting are used together, the results can be breathtaking. For example, a designer might laser cut a beautiful pattern into metal and then use sandblasting to enhance the surface texture. The combination of these techniques can turn a simple design into a stunning piece of art.

This collaboration is what makes custom fabrication so exciting. It allows artists and designers to push boundaries and explore new ideas. They can create not only functional items but also pieces that tell a story or evoke emotions.

Conclusion

In the journey from concept to creation, sandblasting and laser cutting are indispensable tools. Sandblasting prepares surfaces, while laser cutting adds precision and creativity. Together, they enable artisans to bring their visions to life, resulting in unique and beautiful creations.

Custom fabrication is about more than just making things; it’s about expressing ideas and emotions through carefully crafted pieces.

Post Comment